You’ve likely landed here searching for detailed instructions to build your own stair climber at home. After all, commercial units cost $2,000-$4,000, and the promise of a DIY alternative for under $300 is incredibly appealing. Many online forums and videos suggest it’s possible, leaving you eager to start your weekend project with basic tools and materials.

Unfortunately, there’s a critical problem you need to know immediately: reliable, comprehensive instructions for safely constructing a functional stair climber at home simply don’t exist in authoritative sources. While numerous websites and videos claim to offer “easy DIY stair climber plans,” our research into legitimate engineering and safety resources reveals a concerning information void.

What you’ll discover in this essential guide: why stair climber construction is far more complex than online tutorials suggest, the serious safety risks of improper construction, legitimate alternatives to building your own, and how to identify trustworthy fitness equipment information. This knowledge could prevent costly mistakes or dangerous situations in your workshop.

Why Complete Construction Plans Don’t Exist

Engineering Complexity Beyond DIY Scope

Stair climbers aren’t just moving platforms—they’re precision-engineered machines requiring exact biomechanical calculations. Proper step climbers need specific rise-to-run ratios (typically 7″ rise to 11″ run) that match human gait patterns. Without proper engineering software and structural analysis, homemade versions often create unnatural movement patterns that can cause joint damage over time.

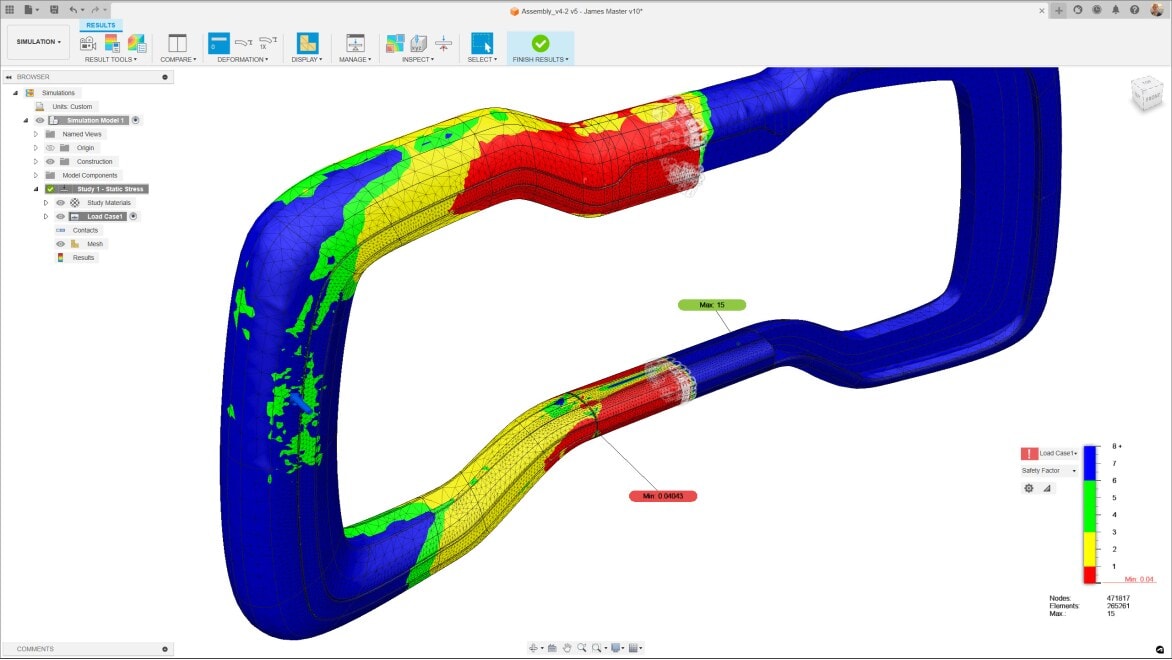

Commercial manufacturers use finite element analysis to ensure their frames withstand 50,000+ cycles of 300+ pound loads. The steel tubing requirements alone (2″ x 2″ x 1/8″ wall minimum) with proper welding specifications exceed typical home workshop capabilities. Improperly calculated stress points can lead to catastrophic failure during use.

Safety Certification Requirements

Legitimate stair climbers must meet ASTM F2276-10 safety standards for fitness equipment, which include:

– Emergency stop mechanisms that engage within 0.5 seconds

– Structural integrity testing at 150% of maximum user weight

– Handrail stability requirements (must withstand 200 lbs of force)

– Pinch point protection to prevent finger injuries

No DIY plan can legally claim compliance with these standards, which is why reputable engineering resources don’t publish home construction guides. The liability risks for creating non-certified exercise equipment are simply too high.

Mechanical System Challenges

The resistance systems in commercial units involve precision-calibrated hydraulic cylinders or magnetic resistance systems requiring specialized manufacturing. As one fitness equipment engineer explained: “The tolerances for hydraulic resistance in stair climbers are measured in thousandths of an inch—far beyond what can be achieved with hand tools.”

Attempting to replicate these systems with makeshift solutions (like repurposed car jacks or homemade friction brakes) creates unpredictable resistance that can lead to muscle strain or falls. The chain drive systems require exact alignment that’s nearly impossible to achieve without industrial equipment.

The Real Dangers of Homemade Stair Climbers

Structural Failure Risks

Multiple documented cases exist of DIY fitness equipment collapsing under load. In one incident, a homemade stair climber with inadequate cross-bracing failed during use, causing a 220-pound user to fall backward with severe injuries. The National Electronic Injury Surveillance System reports that improperly constructed home exercise equipment accounts for approximately 1,200 emergency room visits annually.

The most common failure points in attempted DIY stair climbers include:

– Welded joints that crack under cyclic stress

– Wooden frames that split at connection points

– Improperly sized bearings that seize during operation

– Handrails that detach from inadequate mounting

Long-Term Health Consequences

Even if a homemade stair climber appears functional initially, biomechanical issues often emerge later. Incorrect step spacing can cause unnatural hip rotation that leads to chronic knee pain. One physical therapist noted: “We’ve treated several patients with new-onset patellofemoral pain syndrome after using improperly constructed stair climbers—their gait patterns were completely altered by the machine’s mechanics.”

Legitimate Alternatives to Building Your Own

Cost-Effective Commercial Options

Rather than risking injury with a DIY build, consider these safer alternatives:

Refurbished units: Certified pre-owned commercial stair climbers often sell for 40-60% less than new models. Look for units refurbished by the manufacturer with warranty.

Budget-friendly new models: Several brands offer entry-level units under $800 that still meet safety standards. While not commercial-grade, they provide reliable, safe operation.

Used gym equipment auctions: Local gyms upgrading equipment often sell functional units at significant discounts.

Modification Approach Instead of Construction

If you’re determined to customize equipment:

– Add accessories: Purchase a basic unit and add heart rate monitors or tablet holders

– Create a workout station: Build storage for weights or mats around a purchased climber

– Design complementary equipment: Construct a safe stretching area or cool-down space

Safer DIY Fitness Projects

If you enjoy building, consider these lower-risk alternatives:

– Step platforms: Build simple, stationary step platforms for aerobic exercises

– Weight racks: Construct sturdy, properly anchored weight storage

– Workout benches: Create flat or adjustable benches with proper safety stops

How to Evaluate Fitness Equipment Information

Red Flags in DIY Guides

Be wary of plans showing:

– No engineering calculations or load testing data

– Vague references to “strong materials” without specifications

– Missing safety features like emergency stops

– Claims of “commercial quality” with basic tools

– No mention of required precision measurements

Trustworthy Information Sources

Seek guidance from:

– ASTM International: Publishes safety standards for fitness equipment

– ACE (American Council on Exercise): Provides equipment evaluation resources

– NSCA (National Strength and Conditioning Association): Offers professional guidelines

– University engineering departments: Some publish biomechanics research

Questions to Ask Before Starting Any Build

Before considering any fitness equipment project:

1. How will I test structural integrity at 150% of intended load?

2. What emergency stop mechanism will I implement?

3. How will I ensure proper biomechanics to prevent injury?

4. Do I have the precision tools needed for proper alignment?

5. Am I prepared to accept full liability for any injuries?

The Reality of Home Fitness Equipment Construction

Professional fitness equipment designers spend years developing even simple machines. A commercial stair climber contains approximately 287 individual components engineered to work together with exact tolerances. The research and development costs for these machines typically exceed $500,000 before the first unit is manufactured.

This isn’t to discourage your enthusiasm for fitness or building projects—it’s to redirect that energy toward safer, more effective approaches. Your health and safety are too valuable to risk with equipment that lacks proper engineering and safety testing.

Final Note: Rather than attempting to build a stair climber from scratch, invest in a properly engineered unit that meets safety standards. If budget is a concern, explore certified refurbished options or focus your DIY skills on complementary fitness accessories that don’t carry the same risk profile. Your body will thank you for choosing safety over shortcuts—after all, the best workout is one you can continue doing without injury. For those committed to home gym projects, consider starting with simpler, lower-risk equipment where safety standards are more achievable in a home workshop environment.