You’ve just finished a killer 2K sprint, sweat pooling on the rails as you catch your breath. What you might not realize? That moisture is actively corroding your machine’s metal components while dust particles grind against moving parts. Sweat’s natural acidity eats away at unprotected surfaces, turning smooth strokes into jerky, resistance-heavy pulls within months. Ignoring this daily reality slashes your rower’s lifespan by half and risks expensive repairs down the line.

The fix takes just three minutes after each workout and prevents 90% of common rowing machine failures. This guide reveals the exact cleaning rowing machine protocols used by Olympic training facilities—backed by Concept2’s engineering team. You’ll learn which “harmless” cleaners permanently destroy grips, the precise bleach dilution that disinfects without damage, and the monthly checks that catch hidden wear before it compromises safety. Implement these steps to keep your machine gliding like new for decades, not years.

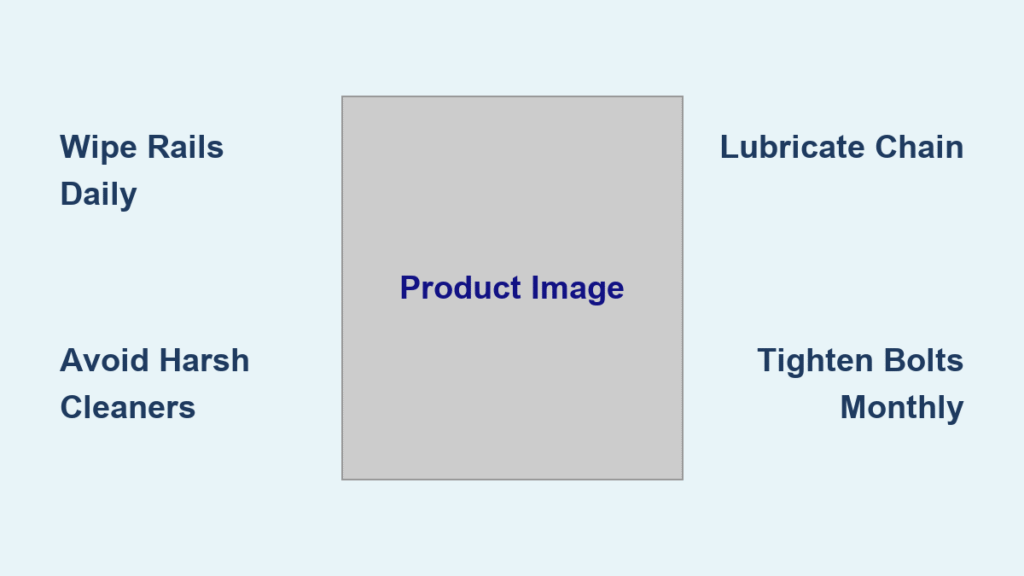

Eliminate Sweat Damage With Daily Rail Wipes

Sweat left on metal rails creates microscopic corrosion pits that attract dust, causing that frustrating “sticky stroke” sensation. Daily cleaning prevents this irreversible wear while maintaining stroke consistency. Focus on the seat rails first—this is where moisture pools and debris accumulates fastest.

Critical daily steps:

– Wipe immediately post-workout using a clean microfiber cloth dampened with water only

– Target high-friction zones: Rails, footplates, handle, and seat cushion seams

– Vacuum rail grooves weekly to extract fabric fibers and dust bunnies

– Dry thoroughly with a second cloth—any residual moisture invites rust overnight

Skipping this routine accelerates rail wear by 300%, according to Concept2’s longevity studies. If you notice a gritty texture when sliding the seat, you’ve already crossed into repair territory.

Avoid These 5 Machine-Killing Cleaners

Household disinfectants marketed for gym equipment often contain chemicals that melt plastic monitors and dissolve grip adhesives. Manufacturers consistently report these culprits in warranty-voiding damage cases.

Never apply these to your rower:

– Bleach (undiluted): Strips protective coatings from aluminum rails

– Ammonia-based cleaners: Permanently fogs plastic monitor screens

– Methylated spirits: Dissolves plastic components and grip binders

– Abrasive scrub pads: Creates micro-scratches that trap grime

– Direct sprays on electronics: Causes internal corrosion in monitors

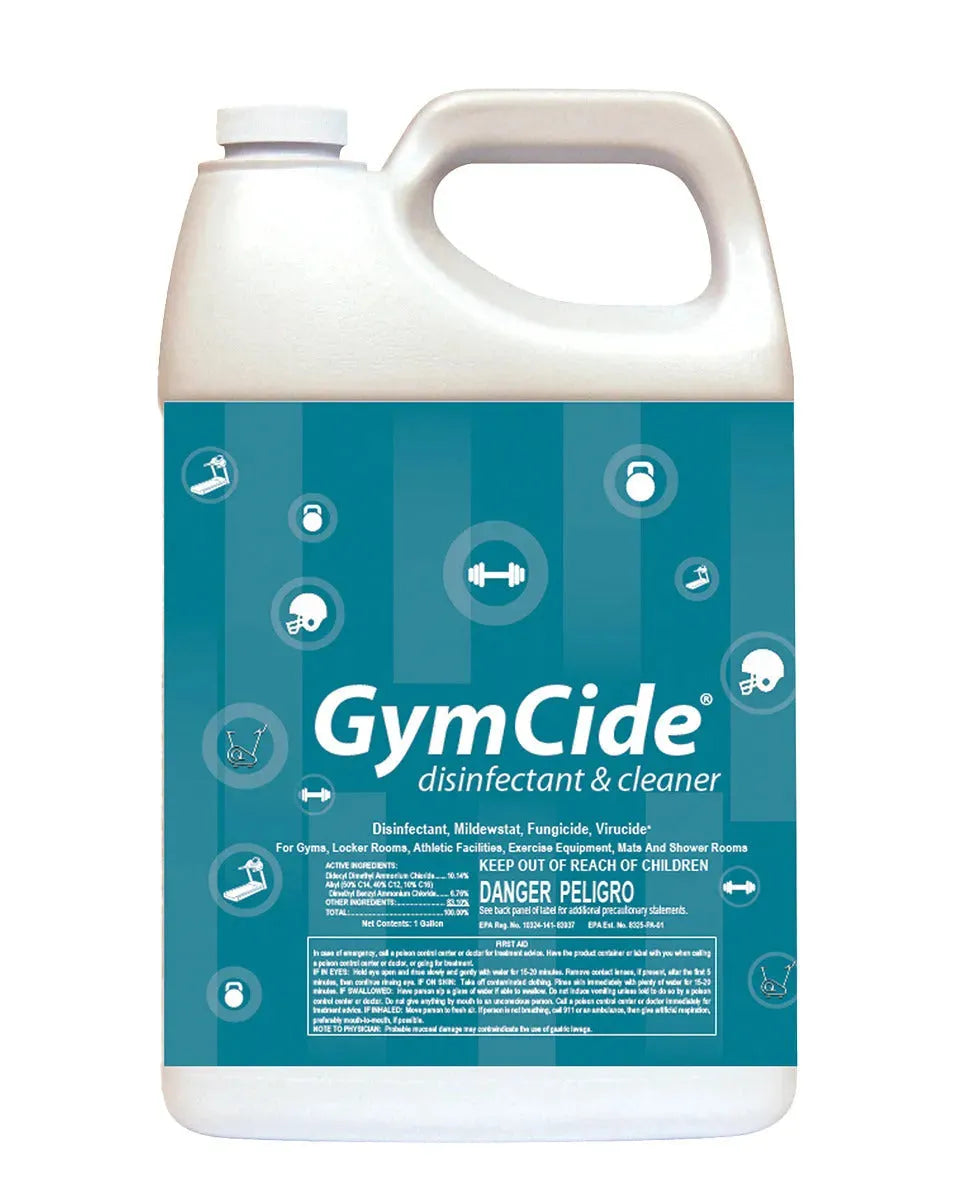

When disinfecting shared equipment, stick strictly to manufacturer-approved methods. One gym owner lost $400 replacing monitors after using Windex—alcohol-based alternatives cause similar damage to microfiber grips.

Concept2-Approved Disinfection Protocol

Gyms and shared spaces require proper disinfection without harming components. Concept2 validates two specific methods that kill pathogens while preserving your machine’s integrity.

Safe Bleach Solution Application

Mix exactly ⅓ cup household bleach (6%) per gallon of water. This diluted solution disinfects without corrosion when used correctly.

Step-by-step process:

1. Pre-clean dirty surfaces with soapy water

2. Apply solution with cloth—never spray near electronics

3. Keep surfaces wet for 60 seconds minimum

4. Rinse immediately with damp paper towel

5. Discard unused solution after 24 hours (loses potency)

Alcohol Alternative (With Critical Exceptions)

Use 70%+ isopropyl alcohol only when bleach isn’t available, but heed these restrictions:

- Safe for: Metal rails, plastic footplates, standard rubber grips

- Unsafe for: Microfiber suede grips (dissolves adhesive backing)

- Application: Soak cloth first—never spray directly

- Drying: Allow 10 minutes air-dry time before use

Alcohol users report handle grip peeling within weeks if applied to suede materials. Always check your grip type first.

Chain Lubrication: The 50-Hour Rule

An unlubricated chain creates grinding resistance that strains the flywheel mechanism. Skipping this maintenance causes premature wear requiring $200+ replacements.

Lubrication must-haves:

– Timing: Every 50 hours of use (≈ monthly for daily rowers)

– Product: Only manufacturer-specified lubricant—generic oils attract dust

– Application: 3-4 drops along chain length while rotating flywheel

– Cleanup: Wipe excess oil to prevent “gunk magnet” effect

Over-lubrication is as damaging as neglect. Excess oil collects debris that accelerates chain wear. Test lubrication success by listening for silent, fluid motion during strokes.

Monthly Bolt Tightening Checklist

Rowing vibrations gradually loosen critical hardware. A single loose footplate bolt can cause dangerous pedal detachment during high-intensity pulls.

Essential monthly inspection:

– Tool required: 5mm Allen key (standard on most models)

– Priority zones: Seat bolts, footplate anchors, monitor mounts

– Tightening rule: Snug until resistance increases—never force past resistance

– Red flags: Rust spots, stripped threads, or cracked welds

Check pedal straps simultaneously for fraying. One loose bolt can misalign the entire rail system, requiring professional recalibration.

Water Tank Maintenance (For Water Rowers)

Stagnant water breeds algae that clogs impeller mechanisms. Skipping purification leads to murky, smelly tanks requiring complete disassembly.

Simple 6-month routine:

– Add one manufacturer-provided purification tablet

– Tablets are free—request replacements via customer support

– Change water only when tablet dissolves completely

– Never use household algaecides—they corrode internal components

This prevents 80% of water rower breakdowns. Without treatment, algae buildup forces costly impeller replacements within 18 months.

Wood Handle Revival With Danish Oil

Unprotected wooden handles dry out, causing cracks that splinter during pulls. Over-oiling creates sticky surfaces that trap grime.

Pro oil application steps:

1. Wipe handle clean with dry cloth

2. Apply ultra-thin oil layer using lint-free rag

3. Wait 5 minutes for absorption

4. Buff vigorously until surface feels dry

5. Cure 8+ hours before next use

Apply every 6-12 months depending on humidity. Skip this, and wood handles typically fail within 3 years of regular use.

Electronic Monitor Lifesaver Tips

Moisture seepage causes 60% of monitor failures. Most issues stem from battery leaks or corroded connections—not internal defects.

Critical monitor care:

– Replace batteries before complete drainage

– Power on unused monitors every 6 months

– Store in climate-controlled spaces (avoid garages)

– Never wipe with wet cloth—damp microfiber only

– Check cable connections monthly for corrosion

Monitor replacements cost $150-$300. These simple steps often extend monitor life beyond the machine’s warranty period.

Storage Secrets to Prevent Accidental Damage

Improper storage causes bent rails and cracked monitors. Folding mechanisms forced incorrectly damage internal hinges.

Space-saving storage rules:

– Always engage folding latches before moving

– Store vertically only on models designed for it

– Cover with breathable cloth (not plastic)

– Position away from doors and high-traffic zones

– Keep rails elevated off concrete floors

One rower cracked their monitor by leaning it against a wall—always use manufacturer-approved upright storage positions.

Long-Term Payoff: 15+ Years From One Machine

Proper cleaning rowing machine habits deliver measurable returns. Concept2’s factory data shows regularly maintained units outlast neglected ones by 300%.

Your maintenance ROI:

– Avoids $200-$500 repair bills annually

– Preserves resale value (well-kept machines sell for 70%+ of retail)

– Maintains stroke calibration accuracy for PR tracking

– Keeps warranties fully valid

– Prevents safety hazards from loose components

A rower used daily for 10 years without maintenance typically requires $600+ in repairs. The same machine with consistent care often functions perfectly at 15+ years.

When to Call Manufacturer Support

Some issues require professional intervention to maintain safety certifications. Attempting DIY fixes on these components voids warranties and creates hazards.

Contact support immediately for:

– Bent or dented rails (affects stroke alignment)

– Cracked frame welds or footplates

– Monitor display failures or calibration errors

– Unusual grinding from flywheel housing

– Request free purification tablets or oil samples

Most manufacturers provide free maintenance supplies and video guides for complex procedures. Never disassemble flywheel housings—that’s strictly professional territory.

Consistent cleaning rowing machine care transforms your equipment from a short-term investment into a lifelong fitness partner. That three-minute post-workout wipe isn’t just about hygiene—it’s insurance against performance-killing wear. Implement these protocols, and you’ll still be chasing PRs on the same smooth-gliding machine a decade from now while others replace theirs every few years. Your future self will thank you when every stroke feels as effortless as day one.