Ever stepped onto an airport moving walkway, effortlessly gliding forward while staying in place? A treadmill recreates that exact physics-defying sensation—but with military-grade precision to handle your daily 5K run or post-injury rehab. If you’ve ever wondered how does the treadmill work when you press “Start,” you’re not alone. Most users treat it as a mysterious black box, but understanding its inner mechanics transforms how you train, troubleshoot issues, and extend its lifespan. In the next few minutes, you’ll discover why premium treadmills feel smoother underfoot, how they auto-adjust to your stride without surging, and the critical maintenance step 90% of users skip that doubles machine longevity.

This isn’t just theoretical—knowing how does the treadmill work helps you diagnose belt slippage before it strains your knees, choose the right model for your needs, and even save $200 on professional repairs. Whether you’re a weekend jogger or physical therapy patient, let’s pull back the console to reveal the engineering marvel beneath your feet.

How Does the Treadmill Work? Electric vs. Manual Drive Systems

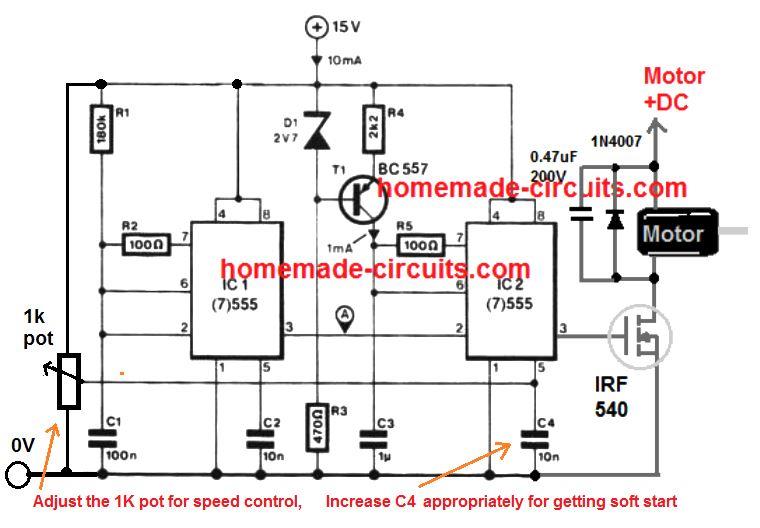

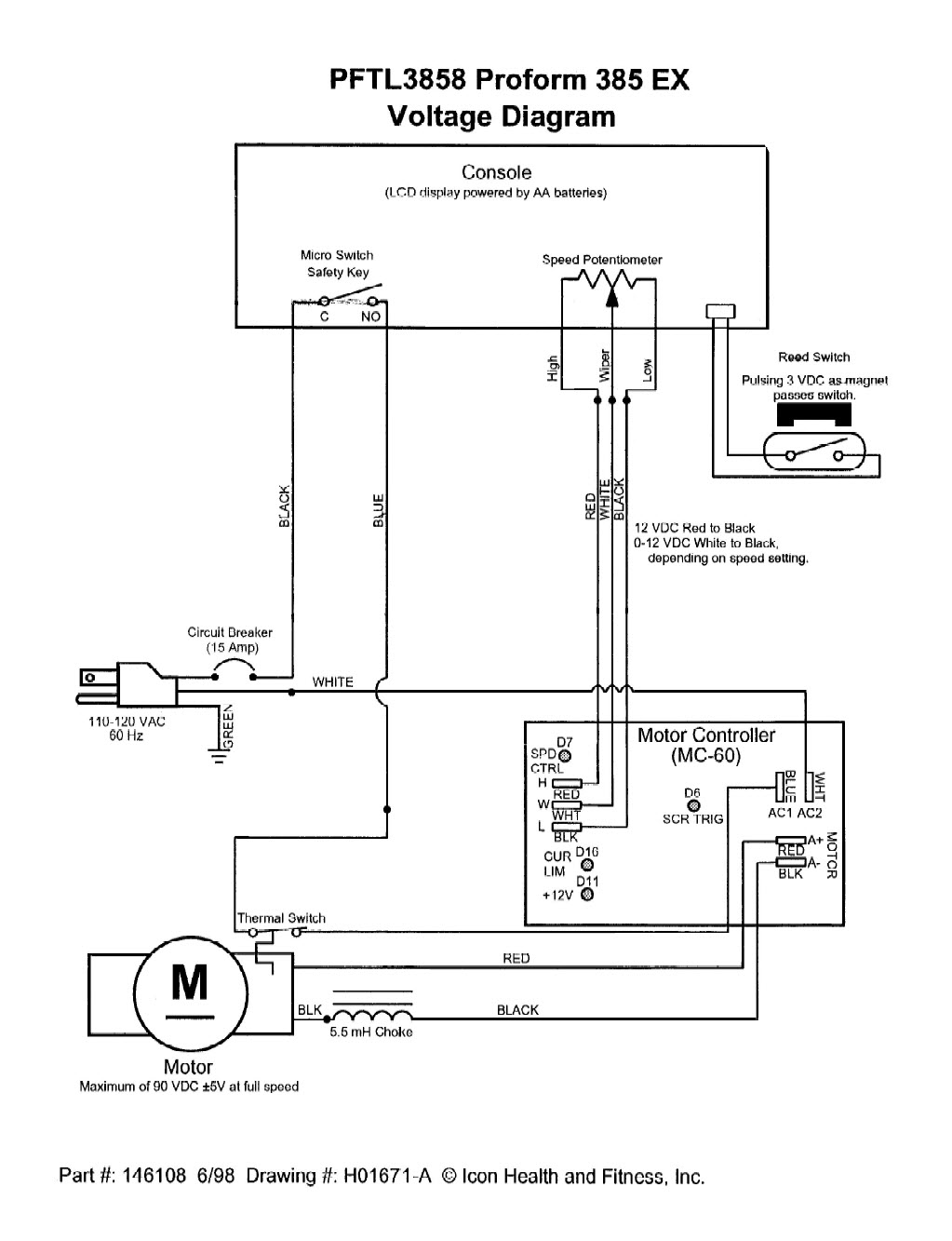

The core magic happens in how the belt moves. Electric treadmills dominate homes and gyms because they deliver consistent, programmable motion. When you select 8 km/h, a 1.5–5 HP DC motor converts wall current into rotational force via pulse-width modulation (PWM). This isn’t random spinning—the controller adjusts power 710 times per second to maintain exact speed, even when your foot strikes create 300-pound impact forces. Commercial units use heavier flywheels (up to 7 kg) to smooth out torque pulses, eliminating the “surging” sensation common in budget models.

Manual treadmills flip this relationship: you power the belt. Your foot pressure against the surface creates motion, while magnetic or mechanical resistance dials intensity. No electricity means unlimited speed potential (if you’re fast enough), but the trade-off is brutal—your quads work 20% harder to overcome belt friction. These excel for sprint training but lack the consistency needed for rehab or precise pacing.

Why Belt Thickness Determines Your Joint Impact

Commercial belts (2.0–2.5 mm thick) use three layers: a rugged polyurethane top, polyester mesh reinforcement, and a wax-impregnated backing that self-lubricates. Thin home-model belts (1.6 mm) heat up faster, increasing friction and joint stress. Look for silicone-infused backing—it reduces surface temperature by 15°C during long runs, cutting impact forces by up to 35% compared to outdoor pavement.

How Rollers Prevent Belt Drift

The front drive roller—covered in vulcanized rubber—grips the belt like tire treads on asphalt. Meanwhile, the rear idler roller uses eccentric bushings to maintain perfect tension (0.5–1% belt elongation). Misalignment here causes dangerous drifting: if the belt shifts 2 cm left/right, it grinds against the frame, accelerating wear. Monthly checks prevent this—adjust tension bolts until the belt has 2–3 cm lateral play at the center.

Motor and Drive System: How Electricity Becomes Motion

Your treadmill’s heart is a brushed or brushless DC motor, but raw power means nothing without intelligent delivery. Home units (1.5–3.0 HP) suffice for walking, but runners need 3.0+ HP to handle 16+ km/h sprints without overheating. Here’s the invisible dance:

- PWM controllers convert AC wall current into variable DC pulses, enabling 0.1 km/h speed increments

- Gear reduction (3:1 to 10:1 ratio) transforms the motor’s 3,000 RPM spin into the 300 RPM needed for smooth belt motion

- Optical encoders track roller rotation 710 times/second, feeding data to the PID control loop

This closed system compensates for your stride in real-time. If you slow down on an incline, the motor instantly adds torque to maintain target speed—no lag, no jolts.

Why Medical Treadmills Handle 45 km/h Sprints

Hospital-grade units (like NASA’s ISS treadmill) use 4.5 kW motors with dual cooling fans and aerospace-grade bearings. They pair with heart-rate-controlled protocols where the belt slows down if your pulse exceeds safety limits—critical for cardiac rehab.

Incline Mechanisms: How Treadmills Simulate Hills and Declines

That “10% incline” button triggers a hidden engineering feat. Screw jacks—12–24V linear actuators—lift the front frame via threaded rods, creating uphill resistance. Premium models add rear actuators for negative grades (-6%), using Hall-effect sensors to maintain ±0.5% accuracy. When you select 12% grade, the system calculates the exact force needed to mimic hill climbing, adjusting motor torque 10x faster than consumer models.

The Shock-Absorption Secret Top Brands Hide

Beneath your feet, elastomer dampers (rubber grommets or air bladders) compress 2–6 mm per stride. But elite treadmills use progressive cushioning: softer elastomers under your heel absorb initial impact, while firmer supports near the toes aid push-off. This reduces tibial stress by 25% versus rigid decks—key for injury-prone runners.

Electronic Safety Systems: How Your Treadmill Protects You

That red clip isn’t just plastic—it’s your lifeline. The safety tether connects to a reed switch; if you fall, it instantly cuts motor power. But modern systems go further:

- Handrail heart sensors detect ECG signals through stainless steel plates. If your pulse drops to zero, the belt auto-stops.

- Capacitive sensors in the console detect missing footfalls after 5 seconds, halting the belt mid-stride.

- Commercial units add emergency mushroom buttons that physically break the circuit—no software delay.

Why You Should Never Skip the Warm-Up Protocol

Starting at 0.5 km/h for 60 seconds lets the belt reach full traction before you step on. Skipping this causes micro-slippage between deck and belt, creating heat that degrades lubrication. Always walk 3–5 minutes at 2% incline to activate elastomer dampers before sprinting.

Control Software: How Speed and Incline Stay Perfectly Adjusted

Budget treadmills use basic “on/off” speed control, causing that annoying surge-slow cycle as you run. High-end units employ adaptive PID algorithms that:

- Predict drag from your foot strike milliseconds before impact

- Pre-emptively boost motor power to maintain belt velocity

- Adjust incline resistance in 0.1% increments for seamless hill simulation

This is why hospital treadmills feel “springy”—they’re actively countering your biomechanics.

Program Modes That Actually Work

- Cardio/HR Control: Belt speed auto-adjusts to keep your heart rate within ±5 bpm of target

- Race Simulation: GPS-linked courses dynamically change incline/speed to match real terrain

- Medical Protocols: Integrates with ECG devices for stress tests like the Bruce Protocol

Home vs. Commercial Treadmill Specs: What Matters for Your Use Case

| Feature | Home Models | Commercial Units |

|---|---|---|

| Motor Power | 1.5–3.0 HP | 3.0–5.0 HP |

| Belt Thickness | 1.6 mm (2-ply) | 2.5 mm (3-ply) |

| User Capacity | 100–150 kg | 180–230 kg |

| Deck Length | 120–140 cm | 150–160 cm |

| Maintenance Cycle | Every 200 km | Every 50 hours |

Critical insight: Home treadmills overheat after 45 minutes of running. If you log 5+ hours weekly, invest in commercial-grade cooling fans and thicker belts.

Daily Maintenance That Doubles Treadmill Lifespan

Most failures stem from neglect—not poor engineering. Follow this 5-minute routine:

- After every run: Wipe sweat with silicone-based cleaner (alcohol degrades belts)

- Weekly: Vacuum debris from motor compartment—dust causes 68% of overheating failures

- Monthly: Check belt tension; adjust rear bolts if center play exceeds 3 cm

- Every 150 km: Apply silicone wax to the deck underside (never top surface)

Pro tip: Flip reversible decks at 50% wear. Replace when surface glazing appears—a shiny, hardened layer that increases friction by 40%.

Understanding how does the treadmill work turns passive users into informed operators. You’ll spot belt misalignment before it strains your knees, choose models with medical-grade shock absorption for joint protection, and perform $150 repairs yourself. Remember: the belt’s hum isn’t magic—it’s precision engineering calibrated to your stride. Treat it right with monthly tension checks and proper lubrication, and your treadmill will deliver 10,000+ miles of reliable service. Now step up, clip in, and own your workout.