That annoying squeak during your morning run? The belt suddenly grabbing underfoot? These aren’t normal workout noises—they’re screaming warnings that your NordicTrack treadmill needs lubrication. Without proper silicone treatment, the belt grinds against the deck like sandpaper on wood, accelerating wear on expensive components. This friction not only ruins your workout experience but can slash your machine’s lifespan by years. The good news: NordicTrack’s official lubrication process takes just 15 minutes and costs under $15. In this guide, you’ll learn exactly when and how to oil your NordicTrack treadmill correctly—no guesswork, no machine damage, just smooth, quiet runs for years to come.

Spot Exactly When Your Treadmill Needs Lubrication

Hit the 3-Month or 130-Mile Oil Deadline

Don’t wait for problems to appear—mark your calendar religiously. NordicTrack mandates lubrication every 90 days OR after 130 miles of use, whichever comes first. Heavy users logging 5+ miles daily should oil monthly, while casual walkers might stretch to 4 months. But here’s the critical detail most users miss: even if you barely use your treadmill, annual lubrication is non-negotiable. Silicone degrades over time, leaving your belt vulnerable during that first post-holiday workout.

Perform the 30-Second Dry Deck Test

Skip complicated diagnostics with this foolproof method:

1. Unplug the treadmill (never skip this safety step)

2. Slide your fingers under the belt’s center point

3. Rub the deck surface beneath the belt

Your verdict? Bone-dry deck = immediate oiling required. A slight oily residue means you’re safe for another month. This test beats mileage tracking for accuracy—it directly measures the friction point where damage occurs. Pro tip: Do this test monthly while wiping down your machine.

Recognize These Critical Warning Signs

Squeaking is the most obvious distress signal, but don’t ignore these subtler red flags:

– Belt slippage where your feet suddenly slide backward mid-stride

– Increased resistance making walking feel like trudging through mud

– Visible fraying along belt edges (especially near the front roller)

– Burning smell during extended use (indicates extreme belt/deck friction)

Ignoring these signs risks catastrophic damage. A dry belt can overheat the motor in under 20 minutes of use, triggering costly repairs that void warranties.

Assemble the Only Supplies NordicTrack Approves

Why 100% Silicone Lubricant Is Non-Negotiable

You’ll find $3 “treadmill lubes” at big-box stores, but NordicTrack explicitly forbids anything except pure silicone-based lubricant. Here’s why:

– WD-40 and petroleum products (like 3-in-1 oil) dissolve belt polymers within weeks

– Vegetable oils attract dust that turns into grinding paste

– Spray lubricants create inconsistent coverage and overspray mess

Invest $10-$15 in a 4-ounce tube of 100% silicone lube (like NordicTrack’s official kit). A single tube lasts 3-5 years of maintenance. Pro tip: Store it upside-down to prevent nozzle clogging.

Essential Tools Checklist

Gather these before starting:

– Allen wrench or screwdriver (matches your rear roller bolts—check manual)

– Microfiber cloth (for wiping excess lube)

– Gloves (silicone stains fabrics permanently)

– Optional: NordicTrack’s applicator wand (prevents messy hand contact)

Never substitute tools—using the wrong size wrench can strip bolt heads, turning simple maintenance into a repair nightmare.

Prepare Your Treadmill for Safe Lubrication

The Power-Down Protocol Most Users Skip

Unplug the machine from the wall outlet—do not rely on the console power switch. Treadmills store electrical charge in capacitors that can deliver shocks even when “off.” Clear a 3-foot radius around the machine to avoid tripping during belt rotation. This isn’t just safety theater: NordicTrack technicians cite improper power-down as the #1 cause of DIY lubrication accidents.

Verify Belt Tension Before Proceeding

Improper tension ruins lubrication effectiveness. Here’s how to check:

1. Lift the belt’s center with two fingers

2. Ideal clearance: 2-3 inches from the deck

If you can lift it more than 3 inches, the belt’s too loose (causing slippage). Less than 2 inches means it’s too tight (accelerating wear). Adjust tension bolts at the rear roller before applying lube—loosen equally in quarter-turn increments until you hit the 2-3 inch sweet spot.

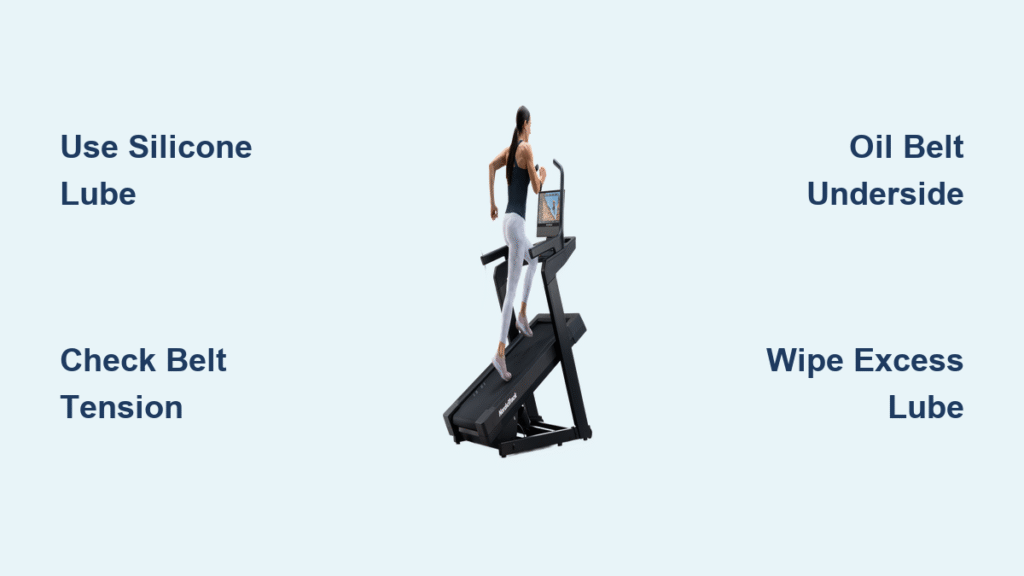

Apply Silicone Like a NordicTrack Technician

The 6-Step Lubrication Sequence

Follow this exact order to avoid wasted lube or machine damage:

1. Slide nozzle under belt at the midpoint (avoiding front/rear rollers)

2. Dispense in zigzag pattern from front to back (6-8 inches total coverage)

3. Use only 1-2 ounces—that’s a 4-inch line of lube, not a puddle

4. Rotate belt manually 10 full revolutions (walk it backward)

5. Re-tighten tension bolts to the 2-3 inch lift standard

6. Run at 3 mph for 3 minutes to fully distribute lube

Critical mistake alert: Never apply lube while the belt’s moving. You’ll get uneven coverage and risk hand entanglement.

Eliminate Dangerous Excess Lubricant

After your test run, inspect the belt edges. Wipe any visible silicone with your microfiber cloth—pooling lube attracts dirt that grinds the deck. If lube drips onto your floor, you’ve used 2X the necessary amount. Run an extra 2 minutes at 2 mph to absorb excess, then wipe again. Over-lubrication causes more problems than under-lubrication, including belt slippage and motor strain.

Avoid These Costly Oiling Mistakes

Never Lubricate These Components

NordicTrack’s engineering team confirms: only the walking belt/deck interface needs lube. Avoid these dangerous targets:

– Roller axles (they’re sealed bearings—lube washes out instantly)

– Incline mechanism (causes hydraulic fluid breakdown)

– Motor housing (attracts dust that overheats electronics)

Applying silicone to rollers creates a slippery hazard where the belt can derail during use. If rollers squeak, they likely need replacement—not lubrication.

Spot Over-Lubrication Before It Damages Your Machine

Excess lube isn’t “better protection”—it’s a magnet for dirt that creates abrasive paste under the belt. Warning signs:

– Belt feels “sticky” during low-speed walking

– Visible oil pooling at treadmill’s rear

– Black streaks on belt edges (dirt mixed with lube)

If you’ve over-applied, run the treadmill at 4 mph for 5 minutes with a dry cloth pressed against the belt’s underside to absorb excess. Never restart workouts until all visible lube is gone.

Fix Persistent Squeaks After Proper Lubrication

Diagnose Hidden Issues in 5 Minutes

If squeaking continues after correct oiling, your problem isn’t lubrication—it’s mechanical. Immediately check:

– Front roller bolts (tighten snugly—loose bolts cause belt wobble)

– Motor drive belt (should deflect ≤½ inch when pressed)

– Belt alignment (centered over deck—adjust tracking bolts if offset)

Vacuum debris from under the belt first. Dust buildup mimics lubrication failure by creating grinding points. Use a crevice tool to remove particles trapped near the front roller.

Maintain Peak Performance Beyond Lubrication

Monthly Belt Inspection Checklist

After oiling, establish this 2-minute ritual:

– Run fingers along edges for fraying or cracks

– Check for centering (belt shouldn’t ride >¼ inch off deck centerline)

– Test tension (maintain 2-3 inch lift clearance)

– Inspect for cuts (stop using immediately if found)

A damaged belt can shred in seconds, potentially damaging the deck underneath—a $200+ repair. Replace belts showing deep cracks or edge fraying before your next oiling.

Create a Foolproof Maintenance Log

Track these critical details after every service:

| Date | Miles Used | Lube Applied (Y/N) | Next Due |

|——|————|———————|———-|

| 6/1 | 128 | Y | 9/1 |

Set phone reminders for your next deadline. NordicTrack’s warranty requires documented maintenance—you’ll need proof if motor issues arise.

Know When to Call NordicTrack Professionals

Red Flags That Mean Stop Using Immediately

Do NOT attempt further DIY fixes if you notice:

– Belt slippage persists after tension adjustment and lubrication

– Grinding noises from the motor housing

– Visible belt damage deeper than surface scratches

– Error codes like “ERR 05” appearing post-lubrication

These indicate internal failures where improper handling could void your warranty. Continuing to use the machine risks electrical hazards or complete motor burnout.

Access NordicTrack’s Direct Support Channels

For urgent issues:

– iFIT Member Care: Call 1-833-680-4348 (faster than general customer service)

– Live Chat: Use NordicTrack.com’s support portal (mention “treadmill lubrication issue” for priority routing)

– Manual Lookup: Search “[Your Model] + service manual” (e.g., “NordicTrack T 6.5s service manual”)

Have your model number ready (found under the console or on the rear frame). Most technicians confirm 70% of “lubrication emergencies” stem from using wrong lube types—always stick to 100% silicone.

Your NordicTrack treadmill should glide like a luxury sedan, not grind like a rusted hinge. By oiling with pure silicone every 3 months or 130 miles—and avoiding household lubricant disasters—you’ll add 5+ years to your machine’s life. That squeak you hear right now? It’s your last warning before major damage sets in. Grab that silicone tube today: Your future self will thank you when you’re still running smoothly while others replace burnt-out motors. Mark your next oiling date before stepping off this treadmill—your consistent maintenance is the only upgrade that pays off forever.